From Lab Models to Real Vehicles: College of Engineering Leadership Advisory Board visits U-M Automotive Research Center

ARC’s research for the U.S. Army develops new technologies that benefit the public.

The research in progress at the University of Michigan’s Automotive Research Center (ARC) was on display on October 17, 2025, when the center welcomed more than 20 industry, government and academic leaders who comprise the Dean’s Leadership Advisory Board.

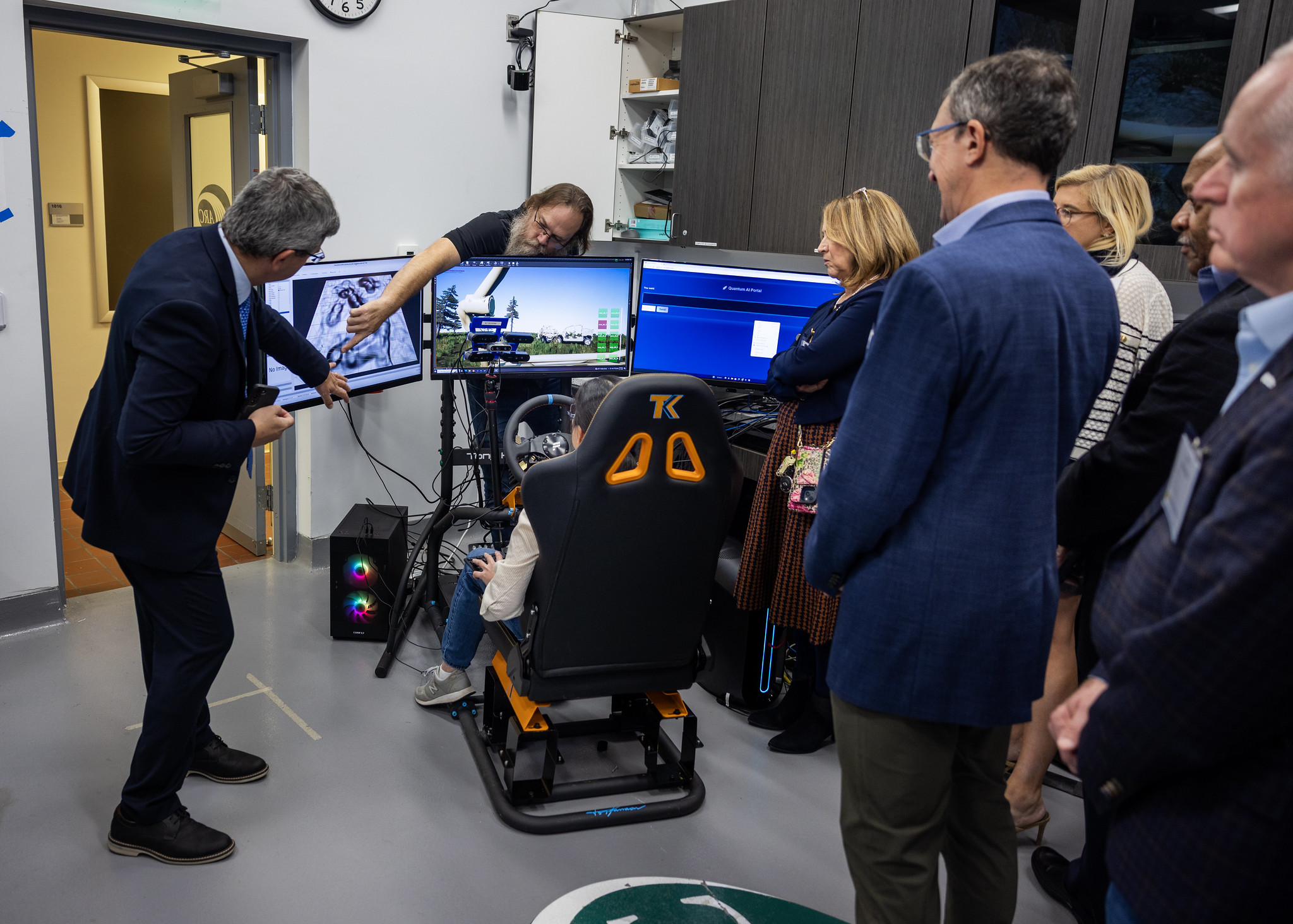

Board members participated in interactive demonstrations of new ARC solutions that turn models into working systems for the government and for industry, giving them the opportunity to take part in large-screen, real-time demonstrations using live vehicle feeds and multi-monitor displays not often offered to the public.

Bogdan Epureanu, ARC Director, opened the visit with a short briefing on ARC’s work, partners, and how results move from lab to field. Visitors joined students and researchers in an Auto Lab where Epureanu highlighted recent achievements and ongoing research, underscoring ARC’s role in driving advances during a global push for self-driving systems, safe/verified AI, and solutions useful for both defense and civilian use.

“Today you will see how we turn models into hardware and software ready to use outside the lab faster and safer. Your guidance helps us serve the common good,” said Epureanu. “The innovations useful for both defense and civilian use created here at Michigan directly influence how industry and defense partners worldwide approach the next generation of mobility challenges.”

Conversations throughout the tour included ARC’s plans for small trial projects starting soon with government partners, shared datasets with clear rules for access and security, and joint proposals that connect education, research, and moving lab results into real-world use.

What the Board saw in the demos is the same approach ARC will carry forward: models made real, measured carefully, and improved with each cycle—guided by LAB feedback and aligned with Michigan Engineering’s mission.

“Thank you for engaging with our people and our platforms. Your feedback sharpens our next cycle of experiments and transitions—and helps our students grow into the engineers our nation needs.” said Epureanu.

Following the visit LAB Chair Jim Adox shared his excitement in a LinkedIn post: “Engineers love to see the hardware, and for me one of the most interesting parts of our meeting was a hands-on deep dive into the cutting-edge work happening at the UM’s Automotive Research Center, which is truly at the forefront of developing advanced vehicle technology…The impact of their work, from basic scientific discoveries to deployable technologies for the Army and industry partners, is truly impactful. I even saw uses of their technology and systems in healthcare.”

Board members experienced unique demos

The demos began at a steering wheel and pedals facing a 185 sq. ft screen. Board members “drove” up a steep, uneven hill while the system recorded every turn of the wheel and press of the brake. This hill-climb station allows everyone to see how engineers test traction and control in the lab first, so settings can be tuned before anyone takes a real vehicle onto rough ground.

A few steps away, a headset showed a live video feed from a small camera mounted on the vehicle. Looking through the “vehicle’s eyes,” a person could steer it from a safe distance. While the vehicle moved, engineers recorded data and kept safety interlocks—automatic limits that prevent unsafe actions—switched on. This is how teleoperation works, and it is also how the team prepares for higher levels of autonomy.

Next, an MRZR off-road vehicle stood ready with its sensors running. Screens showed what the sensors “see”: regular video, and LiDAR (a laser scan that measures distance to map the surroundings). Seeing those live signals made it clear that ARC’s models connect to real hardware, not just to simulations.

Across multiple monitors, several virtual vehicles responded to spoken instructions. The director said simple commands in plain English, and a large language model—a type of AI that understands and follows human instructions—turned those words into control commands for the vehicles on the screen. A person can take control instantly, and safety checks stayed active in the background.

Finally, the group saw how ARC measures driver mental effort. Eye-tracking glasses recorded where a driver was looking, and thermal cameras showed heat patterns on the face. Together, those signals help estimate cognitive load—the driver’s mental effort—so the team can design interfaces that are easier and safer to use, with a person supervising who can take control at any time.

Throughout the room, dashboards made the progress easy to understand what was demonstrated and what moved toward use. The thread was consistent from station to station—start with a model, check it with data, connect it to a real vehicle, and measure the result.

Fast paced research drives innovation

Students and researchers stand at the same stations visitors saw—the hill-climb wheel and pedals, the vehicle-view headset, the M-RZR sensors, the multi-monitor control wall—and turn model ideas into tested actions. Students join project teams early and often, deliver results ready for our partners to use, and flow into internships, veteran pathways, and short training sessions that keep skills current.

The labs and the data make the pace possible. Specialized testing setups shorten the jump from simulation to vehicle. Carefully prepared datasets let teams try new ideas quickly and compare them fairly. Everything is tied together by a digital thread—a clear, traceable link from data to models to code to the vehicle—so results are repeatable, secured, and shared with the right partners.

Safety and accountability are built in from day one. A person supervises and can take over at any time. Checklists, automatic records of what was done, and security rules and protections keep experiments disciplined and trustworthy. Because the tools and teams are ready, outcomes follow: defense-focused trial projects, startups when the fit is right, and executive dashboards that show what transitioned, and what is next.

That is the rhythm the LAB members watched across the stations—start with a model, check it with data, connect it to a real vehicle, measure the result, and feed the lessons back in. With LAB guidance, each loop runs faster and with more impact.