Intelligent Power Systems

Annual PlanScalable Stack Battery Thermal Model

Project Team

Government

Yi Ding, Matt Castanier, U.S. Army GVSC

Faculty

Jason Siegel, University of Michigan

Industry

Dyche Anderson, Ford Motor Co

Student

Amanda Klein, Youngki Kim, University of Michigan

Project Summary

Duration of this add-on project was 2 years, ending in 2012.

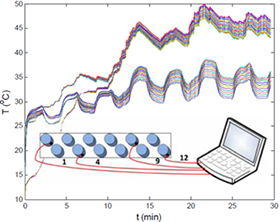

Lithium-ion battery packs are replacing other battery chemistries for portable electronics due to their higher energy density. The military BB2590 pack is used in many military communications and army robotic applications without any active cooling mechanisms. Lithium-ion batteries have a constrained window of operating temperatures (-10 to 50C), with an optimal operating temperature near at 27 degrees C. The core temperature is to be kept lower than 60 degree C for battery life and safety concerns. This constraint poses a unique thermal and monitoring challenge for army vehicles that operate in very hot environments.

Previous work in this project has produced models of parameterization and core temperature estimation for Li-ion chemistry cylindrical cells. In this project, we test our methodology and experimentally validate it using a BB2590 battery pack. Furthermore, we model the pack thermal behavior for the “drive cycle” taken from “Baseline Field Testing of BB-2590 Lithium-Ion Batteries using an iRobot FasTac 510 Robot” [GVSC report No. 21320]. This battery has a complex geometry of the stacked cylindrical Li-ion cells in the BB2590 pack. An additional goal is to develop a state of charge and a max-temperature estimation algorithm to be used for battery controls and power management expecting potential improvement of the range and the mission coverage of the robot powered by these packs.

Publications:

- Xinfan Lin, Hector Perez, Jason Siegel, Anna Stefanopoulou, Yi Ding, Matthew Castanier, “Parameterization and Observability Analysis of Scalable Battery Pack for On-Board Thermal Management,” In Les Rencontres Scientifiques d’IFP Energies nouvelles – Int. Scient. Conf. on hybrid and electric RHEVE Dec 2011. (mirror site 1, site 2, site 3)

- Xinfan Lin, Hector Perez, Jason Siegel, Anna Stefanopoulou, Yonghua Li and R. Dyche Anderson, “Parameterization of a Lithium Ion Battery Thermal Model and Adaptive Observer Design for On-board Thermal Management System,” presented at the American Control Conference (ACC) 2012.

- Xinfan Lin, Hector E. Perez, Jason B. Siegel, Anna G. Stefanopoulou, Yonghua Li, R. Dyche Anderson, Yi Ding, and Matthew P. Castanier, “Online parameterization of lumped thermal dynamics in cylindrical lithium ion batteries for core temperature estimation and health monitoring,” IEEE Transactions on Control System Technology, in print 2013 doi:10.1109/TCST.2012.2217143 (mirror site 1)

- Hector E Perez, Jason B Siegel, Xinfan Lin, Yi Ding, and Matthew P Castanier, “Parameterization and validation of an integrated electro-thermal LFP battery model,” In 2012 ASME Dynamic Systems Control Conference, Oct 2012, 2012. (mirror site 1)

Other research output:

- Estimating Core Temperatures of Battery Cells in a Battery Pack, Xinfan Lin, Anna Stefanopoulou, Yi Ding, Matthew Castanier U-M Ref. No. 5192 provisional patent application filled on May 23, 2012. This application has now been assigned U.S. Serial No. 61/650,760.

- Workshop delivered on the model and the pack observability approach in March 2011 at GVSC.

- Hands-on workshop with software training August 2012 for GVSC CASSI and GVPM, Energy Storage engineers.