Intelligent Power Systems

Annual PlanValidation of JP-8 Surrogates in an Optical Engine

Project Team

Government

Peter Schihl, U.S. Army TARDEC

Industry

Taylor Hansen, Controlled Power Technologies, Inc.

Student

Taewon Kim, Xin Yu, Douglas Harriman, Andrew Abdul-Nour, Wayne State University

Project Summary

Project duration: 2013-2015

This project was a collaborative effort with Prof. Violi’s jet fuel surrogate development project. It provided two key contributions to jet fuel surrogate development; empirical autoignition quality data required for prediction of derived cetane number (DCN) of mixtures created from the components of the surrogate palette, and validation experiments comparing global combustion parameters of target and surrogates in military engine-like temperature and pressure conditions.

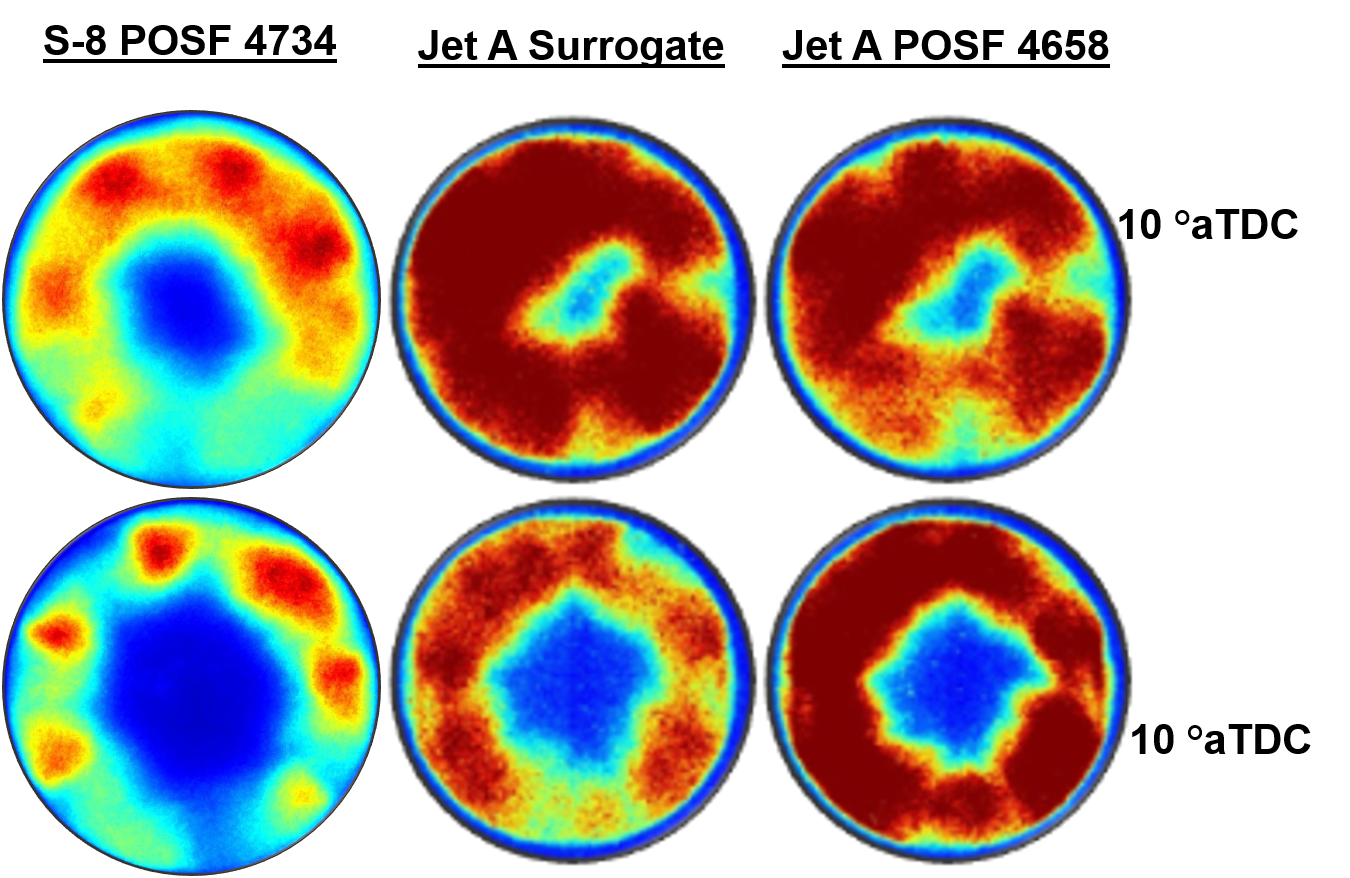

The autoignition data was obtained from experiments conducted on an Ignition Quality Testing (IQT) machine. Mixtures, numbering over one hundred and eighty, created from the six-component palette were tested for ignition delay in the IQT. A six-dimensional regression of the data matrix provided an empirical function modeling the DCN of any mixture created from the six components of the palette and was used by the Violi group’s surrogate optimizer. Global combustion parameters such as fuel liquid penetration length, HCHO*, OH* chemiluminescence, and engine cylinder pressure were used as metrics to determine how closely jet fuel surrogates represent their target fuels. The global parameters were selected based on their sensitivity to fuel physical properties, low temperature reactivity, high temperature autoignition, and burn rate, respectively.

The optical measurements provided both spatial and temporal data, providing further data on how well the surrogates represent target fuel-air mixing behavior. The engine results provided feedback to the surrogate optimizer group. Lastly, to perform a validation in a metal, indirect engine a Jet A surrogate was compared against its target fuel in a standard cetane engine at various compression ratios. Thus, surrogates of Jet A, IPK, and S-8 jet fuels were validated in different combustion systems and under a range of temperature, pressure, and compression ratio conditions.

Publications:

- Luo, X., Yu, X., Zha, K., Jansons, M. et al., “In-Cylinder Wall Temperature Influence on Unburned Hydrocarbon Emissions During Transitional Period in an Optical Engine Using a Laser-Induced Phosphorescence Technique”, SAE Int. J. Engines 7(2):2014.

- X. Luo, X. Yu, M. Jansons, “Simultaneous In-Cylinder Surface Temperature Measurements with Thermocouple, Laser-induced Phosphorescence, and Dual Wavelength Infrared Diagnostic Techniques in an Optical Engine”, SAE Congress, Paper no. 2015-01-1658, Detroit, MI, 2015.

- Li, Z., Yu, X., Lequien, G., Lind, T., Jansons, M., Andersson, O., Richter, M., “Comparison of the Lift-Off Lengths Obtained by Simultaneous OH-LIF and OH* Chemiluminescence Imaging in an Optical Heavy-Duty Diesel Engine,” SAE Technical Paper 2015-24-2418, 2015.

- X. Yu, X. Luo, M. Jansons, D. Kim, J. Martz, A. Violi, “A Fuel Surrogate Validation Approach Using a JP-8 Fueled Optically Accessible Compression Ignition Engine”, SAE Int. J. Fuels Lubr. 8(1):119-134, 2015, https://doi.org/10.4271/2015-01-0906. Also presented at SAE Congress, Paper no. 2015-01-0906, Detroit, MI, 2015.

- Luo, X., Yu, X., Zha, K., Jansons, M. et al., “In-Cylinder Wall Temperature Influence on Unburned Hydrocarbon Emissions During Transitional Period in an Optical Engine Using a Laser-Induced Phosphorescence Technique”, SAE Int. J. Engines 7(2):2014, doi:10.4271/2014-01-1373.

- Yu, X., Zha, K., Luo, X., Taraza, D., Jansons, M., “Simulation and Experimental Measurement of CO2*, OH* and HCHO* Chemiluminescence from an Optical Diesel Engine Fueled with n-Heptane”, SAE Paper 2013-24-0100.

#4.19