Advanced Structures & Materials

integrativeReliability-Based Design Optimization of Tank Track Pad Meta-Material Using the Unit Cell Synthesis Method

Project Summary

Case study performed in 2016.

Contributors (TA 3): Georges M. Fadel, Gang Li, Neehar Kulkarni†, Nicole Coutris† (CU), K.K. Choi (UI), Matthew Castanier, David Ostberg, David Lamb (GVSC), Nicholas Gaul (RAMDO Solutions, LLC) (†Students)

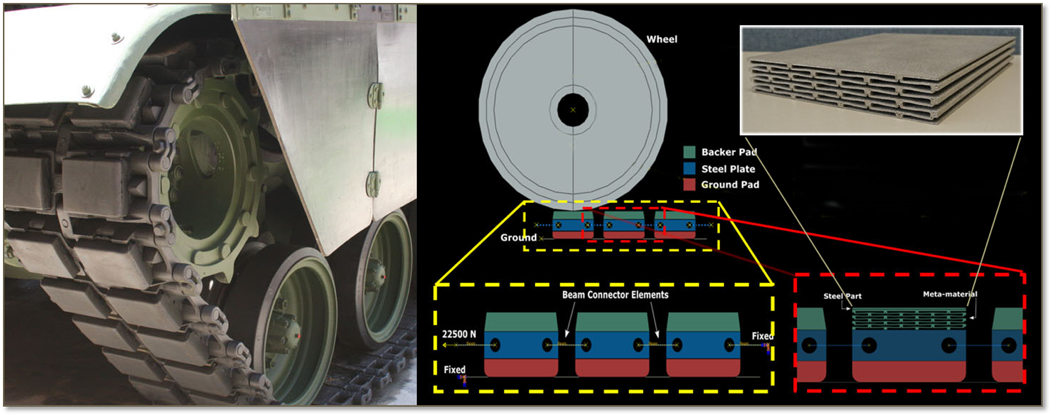

A meta-material with low hysteresis loss and compliance comparable to that of a tank track pad elastomer was designed. The goal was to eliminate hysteretic losses, conduct heat away and mimic the behavior of the elastomer. A new method was proposed to design geometries of unit cells for an elastic meta-material by combining structural components that exhibit geometric nonlinearities under deformation. A design obtained by carrying out deterministic optimization, which closely meets the application specific requirements, was presented and compared to the original track pad under both uniform compression and dynamic wheel loading conditions. Considering variabilities in geometry and material properties in the manufacturing process, a final design that meets the target reliability was obtained by carrying out reliability-based design optimization using RAMDO.