Intelligent Power Systems

Annual PlanLearning Enabled Mission Adaptation for a Hybrid Opposed Piston Engine

Project Team

Government

Dean McGrew, U.S. Army GVSC

Faculty

Robert Middleton, University of Michigan

Industry

Laurence Fromm, Achates Power Inc

Student

Joseph Drallmeier, University of Michigan

Project Summary

Project duration: 2021-2022.

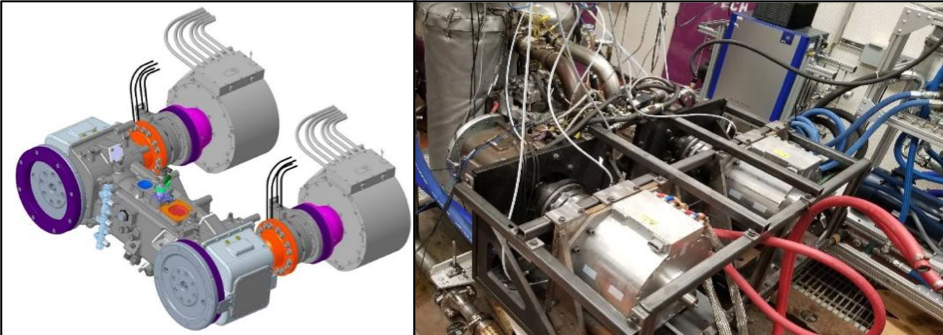

Opposed Piston (OP) engines are characterized by low heat rejection, optimally phased combustion, turbulent combustion, reduced pumping work, and high power to weight ratio. Because the OP engine is nearly perfectly balanced in even a single cylinder configuration, a single cylinder engine can be used in hybrid operation. The main advantage of this approach is it enables one large cylinder vs. several small cylinders, which reduces the surface area to volume ratio of the combustion chamber to minimize heat rejection and maximize efficiency (therefore enabling engine downsizing without a reduction in efficiency).

It also reduces part count which in turn reduces engine cost and logistical support. An opposed piston engine hybridized with two electric motors yields a highly efficient, scalable, robust, and flexible power system. This adaptable power system provides efficient electric power generation over a wide range of power levels for stationary power, hybrid vehicle powertrains, or range extender capabilities for electric vehicles through independent control of the intake and exhaust side piston via separate power takeoff from each crankshaft. In silent watch applications, the hybrid opposed piston engine provides the ability to run at high power setpoints to meet vehicle and mission demands, but also shift operating points on the fly for noise reduction or efficiency improvement as mission requirements evolve while still providing electric power generation.

There are several fundamental research questions that need to be addresses in order to enable this flexibility in engine operation while maintaining high operating efficiency and durability:

- How can the feedback of engine position and cylinder pressure be used by machine learning (ML) algorithms in combination with physics based models to optimize the engine efficiency by controlling the electric power takeoff from each crankshaft?

- How does sizing and efficiency of the electric generators impact the ability to optimize breathing and combustion for mission objectives? and

- How can the ML framework enable the system adapt to changing ambient conditions as well as system faults?

The primary expected outcome of this research is an algorithm that can adapt in real time a set of optimum piston motion profiles for different engine operating conditions. These operating conditions will be optimized for different mission objectives and the simulation models will be used to understand the possible tradeoffs. The system level models developed through this project could also be used for trade-space analysis of the motor size for different applications. Finally, advanced engine diagnostics based on the combination of a physics based model and machine learning could enhance the mission capability of autonomous vehicles by monitoring the quantity of fuel injected, cylinder pressure, electrical current (torque) generation, and crank position to detect any degradation of system performance. This research uses a hybrid opposed piston engine as a testbed for self-calibration, optimization, and self-diagnosis of an advanced fuel-efficient power source.

#4.36